Measuring tapes are among the most widely used tools in both professional trades and everyday household projects. Carpenters, builders, electricians, tailors, and DIY enthusiasts rely on them daily to ensure precision and efficiency. Despite their simplicity and widespread familiarity, measuring tapes include design elements that are frequently misunderstood. One of the most common sources of confusion is the loose, sliding tip at the end of the tape. Many users interpret this movement as a defect or a sign of damage. In reality, the loose tip is an intentional and essential feature designed to improve accuracy.

Understanding why this component exists and how it functions can significantly improve measurement precision and prevent unnecessary frustration. Far from being a manufacturing oversight, the loose tip reflects careful engineering intended to account for different measuring scenarios.

Measuring tapes may appear straightforward, but their design balances durability, flexibility, and accuracy. Every component plays a specific role, and the end hook is no exception. Recognizing its purpose allows users to take full advantage of the tool’s capabilities and avoid misusing or damaging it through misguided repairs.

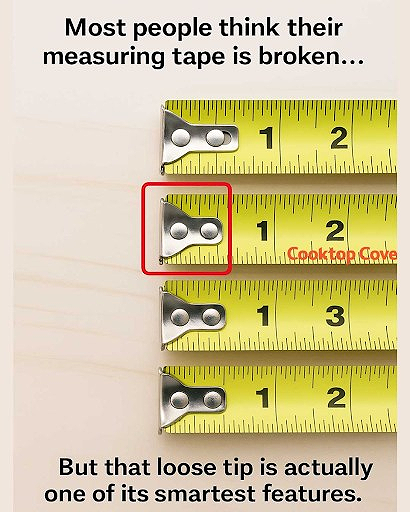

The Widespread Misunderstanding of the Loose Tip

For many users, the first encounter with a loose measuring tape tip raises concern. The metal hook at the end appears to shift slightly back and forth, which can feel counterintuitive for a tool intended to provide exact measurements. This movement often leads people to believe the tape has loosened over time or was poorly assembled at the factory.

This misconception is reinforced by the expectation that precision tools should be rigid and immobile. When something moves unexpectedly, it is easy to assume it is broken. As a result, some users attempt to tighten the rivets holding the tip in place or replace the tape altogether, assuming it can no longer be trusted.

Such actions are not only unnecessary but can also reduce the tape’s accuracy. The movement is not accidental wear; it is a calculated allowance built into the design. Removing or limiting this movement undermines the tool’s ability to compensate for different measuring methods.

How Measuring Tapes Are Engineered for Accuracy

At its core, a measuring tape consists of a thin, flexible strip of metal marked with precise measurement increments. The tape is housed in a case with a spring-loaded mechanism that allows it to retract smoothly. The curvature of the metal strip provides rigidity when extended, preventing it from collapsing under its own weight during use.

The end hook, often referred to as the tip or tang, is attached using small rivets or fasteners. These fasteners are intentionally not fixed tightly. Instead, they allow the hook to slide back and forth by a distance equal to the thickness of the hook itself.

This movement is subtle but deliberate. It ensures that the tape delivers accurate readings regardless of whether the measurement is taken by pushing the tape against a surface or pulling it around an edge. Without this feature, measurements would consistently be off by a small but significant margin.

Inside and Outside Measurements Explained

One of the primary reasons for the loose tip is to account for the difference between inside and outside measurements. When measuring an outside dimension, such as the length of a board or the width of a table, the user typically hooks the tip over the edge and pulls the tape taut. In this case, the hook is pulled outward, and the measurement begins from the inner edge of the hook.

When measuring an inside dimension, such as the distance between two walls or the width of a cabinet opening, the user pushes the tape inward until the hook presses against the far surface. Here, the hook slides inward, compensating for its own thickness so that the measurement remains accurate.

The sliding motion ensures that the zero point of the tape aligns correctly in both scenarios. Without this adjustment, measurements would either be consistently too long or too short, depending on how the tape was used.

The Importance of Hook Thickness Compensation

The thickness of the metal hook may seem negligible, but even a small discrepancy can lead to noticeable errors, especially in precision work. In carpentry, cabinetry, and metal fabrication, measurements must be exact to ensure proper fit and alignment. A difference of even a millimeter can cause gaps, misalignment, or structural issues.

The loose tip automatically compensates for this thickness. When pulled, the hook moves outward by its own thickness. When pushed, it moves inward by the same amount. This design ensures that the measurement markings on the tape correspond accurately to the actual distance being measured.

This self-adjusting mechanism eliminates the need for the user to manually account for the hook’s thickness, reducing the chance of human error and speeding up the measuring process.

Durability and Long-Term Use

Another benefit of the loose tip design is durability. Measuring tapes are often subjected to rough handling, including being dropped, snapped back into their cases, or used in challenging environments. The slight movement in the hook helps absorb impact and reduces stress on the rivets and tape itself.

If the hook were rigidly fixed, repeated impacts could cause the metal to bend or the rivets to loosen unevenly. By allowing controlled movement, the design distributes force more evenly and extends the life of the tool.

This durability consideration is particularly important for professionals who rely on their tools daily. A measuring tape that maintains its accuracy over time is essential for consistent results.

Why Attempts to “Fix” the Tip Cause Problems

Despite the thoughtful engineering behind the loose tip, many users attempt to correct what they believe is a flaw. Common actions include hammering the rivets tighter, gluing the hook in place, or replacing the tape entirely. These efforts often stem from a desire for stability, but they can introduce inaccuracies.

By fixing the hook in one position, the tape loses its ability to compensate for different measuring methods. This results in measurements that are consistently off by the thickness of the hook. Over time, these small errors can accumulate, leading to wasted materials, improper fits, and additional work.

Understanding that the movement is intentional helps users avoid these mistakes and trust the tool as designed.

Variations Across Different Measuring Tapes

While the basic principle of a loose tip is consistent across most measuring tapes, there can be slight variations in design depending on the manufacturer and intended use. Heavy-duty construction tapes may have thicker hooks to withstand rough conditions, while precision tapes used in fine woodworking or tailoring may feature slimmer tips.

In all cases, however, the underlying purpose remains the same: to ensure accurate measurements across different applications. Some tapes may have smoother movement than others, but the presence of controlled play is a common and necessary feature.

High-quality measuring tapes are engineered with tight tolerances, ensuring that the hook’s movement is precise rather than sloppy. Excessive wobble can indicate damage, but a small, consistent sliding motion is normal and desirable.

Practical Benefits for Everyday Users

For everyday users, understanding the purpose of the loose tip can lead to better results and greater confidence in measurements. Whether hanging shelves, cutting fabric, or assembling furniture, accurate measurements reduce frustration and improve outcomes.

Knowing that the tape is designed to self-correct allows users to focus on proper technique rather than second-guessing the tool. It also helps users identify when a tape truly is damaged, such as when the hook is bent or the rivets are loose beyond their intended range.

This knowledge transforms the loose tip from a source of confusion into a reassurance that the tool is functioning as intended.

A Small Feature With a Significant Impact

The loose tip on a measuring tape is a prime example of how thoughtful design can solve practical problems in subtle ways. What appears at first glance to be a flaw is actually a carefully calculated solution to the challenge of measuring both inside and outside dimensions accurately.

By allowing the hook to move by exactly its own thickness, measuring tapes provide consistent and reliable results across a wide range of applications. This feature reduces errors, enhances durability, and simplifies the measuring process for users at all skill levels.

Understanding this design choice not only improves measurement accuracy but also deepens appreciation for the engineering behind everyday tools. The next time the tip of a measuring tape shifts slightly, it can be seen not as a defect, but as a deliberate feature working to ensure precision.